In warehousing, lead time is more than just a buzzword—it’s the heartbeat of operational efficiency. Think of it as the timer that starts when an order comes in and stops when it’s out the door. The faster and smoother that process runs, the happier your customers and the healthier your bottom line. In this article, we’ll explore lead time from a supply chain and warehousing perspective, why it matters, and how you can streamline it to stay ahead of the competition.

Breaking Down Lead Time

Every second counts when it comes to lead time. From the moment an order is placed to when it’s ready for delivery, each step plays a crucial role in keeping operations efficient and customers happy. Let’s walk through the process and uncover the opportunities to streamline each stage.

- Order Placement

The journey begins when a customer places an order—whether it’s a bulk purchase for a business or a single item for an online shopper. Accurate details like quantities, specifications, and delivery preferences set the foundation for success. - Order Processing

Once the order lands in the warehouse, it’s logged and confirmed. This step is all about speed and clarity—smooth systems and clear communication can prevent delays from snowballing later. - Inventory Check and Picking

Next, it’s time to locate the item in stock and pick it from the shelves. This step is faster and more precise when inventory systems are accurate and warehouse automation does the heavy lifting. - Order Packing

With the item in hand, it’s securely packed, labeled, and prepped with any required documentation, like invoices or shipping labels. Proper packing ensures the order arrives in perfect condition and meets shipping standards. - Shipping Preparation

The final stretch involves sorting and consolidating packages for delivery. Coordinated logistics make this step seamless, cutting down on preparation time and keeping shipments on schedule.

Lead Time vs. Cycle Time: What’s the Difference?

In supply chain management, particularly in warehousing and order fulfillment, understanding the distinction between lead time and cycle time is essential for optimizing operations. While both are metrics that track efficiency, they focus on different aspects of the process.

- Lead Time: Lead time represents the duration from when an order is placed to when it is delivered, effectively measuring the total time taken to fulfill the order. For warehouses, this includes everything from order processing to picking, packing, and shipping. Shorter lead times are crucial for meeting customer expectations and staying competitive in an era of fast fulfillment demands.

- Cycle Time: On the other hand, cycle time is an internal measure. It tracks how long it takes to complete specific tasks within the fulfillment process—for example, the time it takes to pick an item from inventory or pack it for shipping. Unlike lead time, cycle time doesn’t include external factors like shipping delays or customer response times.

Understanding both metrics is key to improving operational efficiency. Lead time reflects the overall customer experience, while cycle time highlights bottlenecks within the process. By optimizing cycle times—using tools like warehouse automation and accurate inventory management—you can naturally reduce lead times, creating a faster, smoother fulfillment process that benefits both your business and your customers.

How to Calculate Lead Time

Accurately calculating lead time is essential for improving processes and meeting customer expectations. The formula you use depends on the type of lead time you’re measuring, but the general approach is simple.

The Basic Formula for Lead Time

Lead Time = Order Delivery Date − Order Placement Date

This formula provides a high-level understanding of lead time, but you can break it into smaller stages for more detailed insights.

Supply Chain Lead Time

Supply chain lead time measures the entire process, from procuring materials to delivering the final product. The formula typically looks like this:

Supply Chain Lead Time = Procurement Time + Production Time + Delivery Time

Supply Chain Lead Time Example:

- Procurement Time: 7 days

- Production Time: 12 days

- Delivery Time: 5 days

Total Supply Chain Lead Time: 7 + 12 + 5 = 24 days

Order Lead Time

Order lead time is commonly used in e-commerce and retail, covering the time it takes to process and ship an order:

Order Lead Time = Processing Time + Shipping Time

Order Lead Time Example:

- Processing Time: 2 days

- Shipping Time: 3 days

Order Lead Time: 2 + 3 = 5 days

Why Accurate Calculations Matter

Knowing your exact lead time offers several benefits:

- Improved Planning: Accurate lead time data allows for better production scheduling and resource allocation.

- Customer Satisfaction: Shorter and more predictable lead times enhance the customer experience.

- Cost Control: Identifying bottlenecks helps reduce delays and associated costs.

Understanding and controlling these factors is key to optimizing lead time and running your operations smoothly.

Strategies to Reduce Lead Time

Reducing lead times means rethinking your warehouse operations to boost both speed and efficiency. By implementing strategic changes, you can significantly improve efficiency and keep your supply chain running like clockwork. Here are the top strategies to make a meaningful impact:

1. Foster Clear Communication with Suppliers

Miscommunication with suppliers can derail even the most efficient operations. Strengthen partnerships by implementing these best practices:

- Define Deliverables: Outline product specifications, quality standards, and delivery timelines upfront.

- Set KPIs: Establish measurable key performance indicators to track progress and ensure accountability.

- Regular Check-Ins: Schedule consistent meetings to address challenges and provide feedback.

- Centralized Contacts: Assign clear points of contact to streamline communication.

- Feedback Loops: Create opportunities for mutual feedback to continuously refine processes.

Clear, honest communication fosters trust and minimizes delays, ensuring every party is on the same page.

2. Integrate Your Systems

Disconnected systems lead to blind spots and inefficiencies. Integrating your tools and platforms creates a seamless flow of information:

- Unified Software: Use supply chain management software or vendor portals to share real-time updates and inventory visibility.

- Connected Processes: Ensure your inventory, order management, and shipping systems work together for maximum efficiency.

- Real-Time Alerts: Leverage automation to flag low stock levels or bottlenecks instantly.

System integration not only reduces errors but also accelerates decision-making at every stage of the supply chain.

3. Optimize Inventory Management

Efficient inventory management ensures that products are always available when needed, reducing delays at critical points:

- Demand Forecasting: Use predictive analytics to anticipate customer needs and maintain optimal stock levels.

- Regularly Auditing Inventory: Whether through cycle counting or periodic reviews, ensure data accuracy, uncover discrepancies, and provide actionable insights to optimize stock levels and prevent costly errors.

- Cycle Counting: Regular inventory audits help prevent stock discrepancies and keep operations running smoothly.

An optimized inventory system eliminates the guesswork, helping you meet demand without unnecessary delays.

4. Prioritize Logistics Coordination

Even the best internal processes can falter without effective outbound logistics. Focus on the following to keep things moving:

- Consolidate Shipments: Group orders strategically to minimize shipping times and costs.

- Partner with Reliable Carriers: Build relationships with carriers that consistently meet delivery commitments.

- Track in Real Time: Use GPS and shipment tracking tools to monitor progress and address disruptions proactively.

Proactive logistics planning ensures that what leaves the warehouse gets to the customer as quickly and reliably as possible.

5. Leverage Automation in Order Fulfillment

Automation is a game changer for warehouses looking to streamline processes and shorten lead times. Invest in tools and systems that are fast, flexible, and resilient:

- Smart Picking Systems: Automated picking solutions minimize manual errors and increase speed.

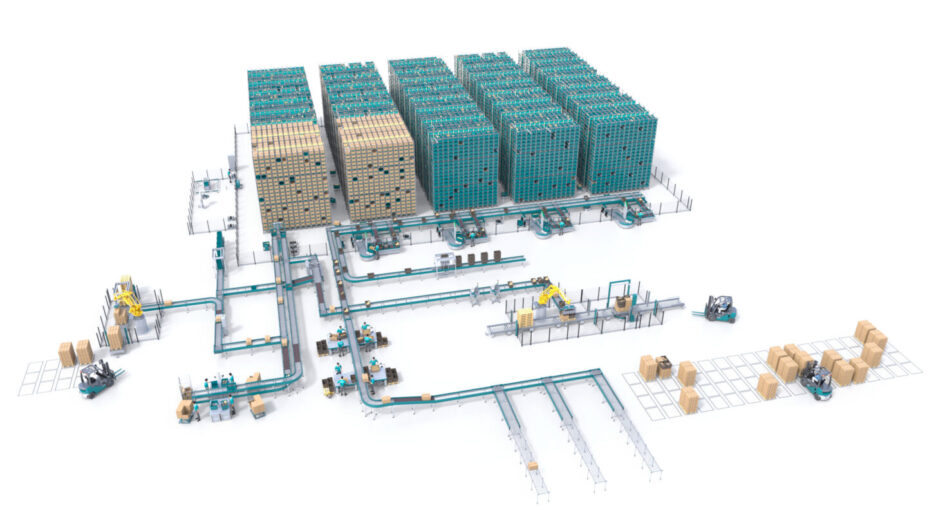

- Robotic Assistance: Use advanced robotics, like Exotec’s Skypod system, that offer high degrees of throughput and flexibility to adapt to changing market and business needs.

- Customization Equipment: Equipment like right-sized packaging allows your business to use boxes that perfectly fit your goods, reducing waste and maximizing truck space.

Automation not only speeds up fulfillment but also improves scalability, helping your warehouse stay responsive to customer needs.

Adopting these strategies can cut lead times, reduce costs, and deliver a seamless experience for your customers. In a competitive market, a well-oiled supply chain is the foundation of success.

Your Path to Shorter Lead Times

Lead time is vital to business success, impacting customer satisfaction, costs, and performance. By optimizing supply chains and leveraging automation, businesses can reduce lead time, transforming it into a powerful competitive advantage for efficient, future-ready operations.

The Exotec Skypod system combines high performance and flexibility for goods-to-person robotic automation, helping reduce lead times. It offers up to 5x the throughput of manual operations and retrieves any SKU in under two minutes, enabling faster shipping and quicker order fulfillment.

Ready to take the next step? Partnering with an innovative automation solution like Exotec’s Skypod® system can help you cut lead times and scale your business effectively.

Featured In

Share

Insights

-

April 15, 2025Top Warehouse Trends for 2025: Future of Automation

-

April 9, 2025Material Handling: Basics, Benefits, & Automation

-

April 4, 2025Complete Guide to Pick-and-Place Automation

News

-

March 24, 2025Exotec Showcases Next-Gen Skypod System at ProMat 2025

-

March 17, 2025Exotec Announces Partnership with Oxford Industries to Implement Next Generation Skypod System in New Multi-Brand Distribution Center

-

February 27, 2025Colruyt‘s Collect&Go continues its automation journey with Exotec

Events

-

May 7, 2025Exodinner: Indianapolis, IN

-

May 22, 2025 | Cincinnati, OHExotour: Cincinnati, OH

-

May 28, 2025Exodinner: Vancouver, BC