The term “3PL” stands for third-party logistics, a concept that has evolved into a cornerstone of modern supply chain management. But what is 3PL, exactly? At its core, it involves outsourcing logistics operations—such as warehousing, transportation, and order fulfillment—to an external provider. While the idea of outsourcing logistics isn’t new, the role of 3PL providers has expanded far beyond traditional transportation and storage services, offering advanced technology, automation, and data-driven solutions to optimize supply chains.

As supply chains grow more complex, managing logistics with limited resources becomes increasingly difficult. Yet, strong supply chain management is essential for companies looking to scale, deliver high-quality products and services, and maintain cost efficiency. From small e-commerce startups to multinational corporations, businesses rely on 3PL providers to overcome these challenges and streamline their supply chains.

Historical Context: The Evolution of 3PL

The origins of 3PL can be traced back to the mid-20th century when businesses first began outsourcing transportation and warehousing to reduce operational complexity. The 1980s saw the rise of 3PLs as globalization took hold, and companies sought partners to manage international shipping and customs. By the 1990s, the deregulation of transportation industries in countries like the U.S. allowed logistics providers to expand their services.

The e-commerce boom in the 2000s further accelerated the growth of 3PL as businesses faced increasing pressure to adapt to shifting consumer expectations. With the rise of online shopping, fast shipping became the norm, driving the need for more agile and scalable fulfillment solutions. To stay competitive, many businesses adopted omnichannel strategies, balancing direct-to-consumer orders, wholesale distribution, and store replenishment while maintaining seamless inventory management across multiple sales channels. However, as warehouses have been challenged to do more, their operations have become more complex.

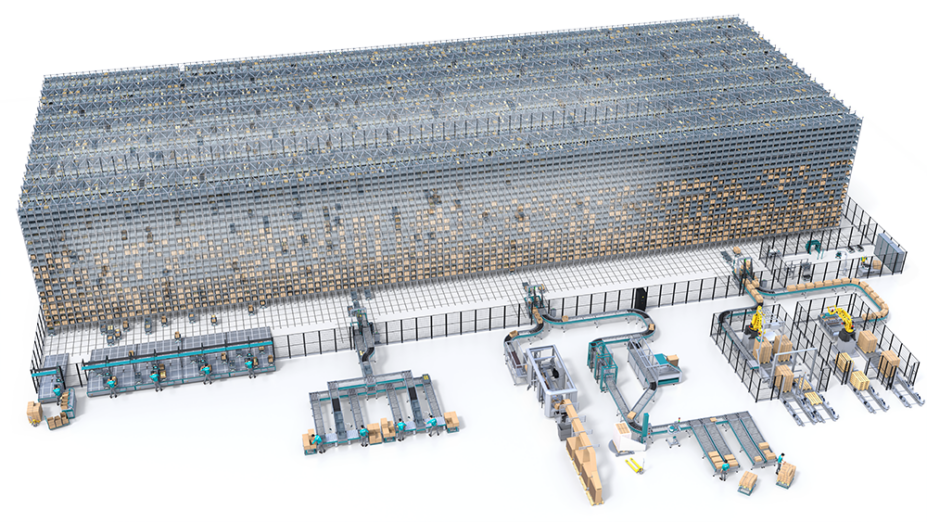

To handle the growing complexity, 3PLs have become technology-driven partners, using automation systems, AI, and analytics to streamline and improve supply chains’ performance. Many are adopting Automated Storage and Retrieval Systems (ASRS) like the Exotec Skypod® system, which uses robotics to transport goods between high-density storage racks and Workstations for picking and packing. The system offers a powerful combination of speed and flexibility, retrieving any ordered item within two minutes. Integrating key warehouse processes—buffering, sequencing, picking, and packing—into a single system reduces the need for external equipment to accomplish many value-added processes, saving space, time, and costs.

Innovative robotic automation system like this are empowering leading 3PL providers to enhance efficiency, scalability, and customer satisfaction in a fast-paced logistics environment.

How 3PL Services Optimize Supply Chains

3PL providers offer services designed to meet the needs of modern businesses. By using advanced automation, they speed up order fulfillment, streamline operations, and improve accuracy—all while adapting to changing demand and market conditions. Here are some key services that 3PL providers offer:

Warehousing and Inventory Management

Warehousing is the backbone of 3PL operations, playing a critical role in inventory management and ensuring businesses can efficiently store, track, and manage products while adapting to fluctuating demand. By outsourcing warehousing to a 3PL, companies eliminate the need to invest in costly facilities, equipment, and technology while gaining access to expertly managed storage solutions. 3PLs also handle staffing, training, and labor management, ensuring warehouses operate efficiently without the burden of in-house oversight. Here are a couple of advanced technologies that enable 3PLs to operate with high efficiency:

- Warehouse Management Systems (WMS): A WMS provides real-time inventory tracking, stock visibility, and automated order processing, preventing overstock or stockouts while optimizing warehouse workflows.

- Robotic Automation: Advanced automated storage and retrieval systems (AS/RS) and autonomous mobile robots (AMRs) enhance warehouse efficiency, improving accuracy and reducing manual labor requirements.

Order Fulfillment and Distribution

3PL providers can oversee the entire order fulfillment process. With advanced fulfillment centers, businesses can achieve faster, more accurate order processing, ensuring they meet growing consumer demands for same-day and next-day delivery.

- Picking, Packing, and Shipping: 3PLs efficiently handle high order volumes by managing the selection of products from inventory (picking), securely preparing them for shipment (packing), and coordinating transportation with carriers (shipping). They ensure accuracy, minimize delays, and optimize packaging to reduce shipping costs.

- Returns Management: Many 3PLs also manage reverse logistics, processing returns quickly

- Kitting & Order Customization: 3PLs often provide kitting, bundling, and labeling services, allowing businesses to ship pre-assembled product sets or customized orders tailored to customer needs.

Transportation and Freight Management

While warehousing focuses on storage and retrieval, transportation logistics handle the movement of goods across local, regional, and international networks. Advanced routing algorithms and freight consolidation strategies are critical for optimizing delivery times and reducing costs. By partnering with 3PL providers, businesses can tap into robust transportation networks without needing to build their own, gaining access to faster and more cost-effective shipping solutions.

The Benefits of 3PL for Growing Businesses

Logistics can be overwhelming. From managing inventory and coordinating fulfillment to scaling operations during peak seasons, businesses face constant challenges in maintaining efficiency. Here are key benefits 3PLs offer:

Access to State-of-the-Art Facilities and Technology

Managing a warehouse requires substantial investment—not just in real estate but also in equipment, automation, and software—to keep operations running efficiently. 3PL providers eliminate this burden by offering businesses access to expertly managed storage and distribution centers equipped with advanced technologies such as warehouse management systems (WMS), automated storage and retrieval systems (AS/RS), and autonomous mobile robots (AMRs). Instead of absorbing the costs of continuous upgrades and maintenance, businesses benefit from the latest innovations without the capital expense.

Workforce and Labor Management Without the Overhead

Beyond infrastructure, 3PLs also take on the responsibility of staffing, training, and labor management, ensuring warehouses operate smoothly without the need for in-house oversight. Recruiting, onboarding, and retaining skilled logistics personnel can be time-consuming and costly, particularly in a labor market facing ongoing shortages. A 3PL provider manages all aspects of warehouse staffing, from hiring and training to shift scheduling and performance optimization, ensuring a highly efficient and well-coordinated workforce.

Enhanced Operational Efficiency

By outsourcing logistics, businesses can focus on their core operations while relying on their 3PL provider’s expertise to optimize supply chain workflows. From warehouse layout design to inventory management and picking strategies, 3PLs leverage best practices and automation to enhance efficiency, reduce errors, and improve turnaround times.

Cost Savings Through Optimization

Leveraging a 3PL’s established network and technology eliminates the need for costly capital investments. Providers use freight consolidation, inventory placement strategies, and demand forecasting to optimize supply chain operations, reducing transportation expenses and minimizing waste. This allows businesses to allocate resources more effectively while benefiting from economies of scale that would be difficult to achieve independently.

Improved Customer Satisfaction

With faster deliveries, improved order accuracy, and streamlined returns processing, businesses can offer the high level of service that today’s customers expect. 3PL providers ensure that fulfillment operations run seamlessly, helping businesses meet next-day and same-day shipping expectations while reducing costly errors. By improving the end-to-end logistics experience, 3PL partnerships enhance customer loyalty and retention.

3PL Across Industries: Tailored Solutions for Unique Needs

While the fundamental goal of 3PL—outsourcing logistics operations—remains consistent, the application of 3PL services varies widely across industries.

- E-commerce: In the e-commerce sector, 3PL providers are indispensable for handling rapid order fulfillment, managing inventory across multiple distribution centers, and facilitating seamless returns. With the rise of same-day delivery expectations, 3PLs rely on advanced automation and real-time tracking to meet these demands.

- Retail: For retailers, 3PLs play a critical role in enabling omnichannel fulfillment. This includes integrating online and in-store inventory, managing reverse logistics, and ensuring timely restocking of store shelves.

- Healthcare and Pharmaceuticals: The healthcare and, in particular, the pharmaceutical industry, depends on 3PL providers for specialized services like temperature-controlled storage, compliance with strict regulatory standards, and secure transportation of sensitive products such as vaccines. Automation and IoT sensors are key to maintaining product integrity.

- Manufacturing: Manufacturers leverage 3PL providers to streamline raw material supply and distribute finished goods efficiently. This often involves a mix of just-in-time delivery models and bulk transportation solutions.

The ability of 3PLs to tailor their offerings to these diverse sectors underscores their importance in modern supply chain management.

Case Study: GEODIS and the Power of 3PL Automation

Introduction to GEODIS

As one of the world’s leading 3PL providers, GEODIS operates in over 168 countries and offers a comprehensive range of logistics solutions. The company’s commitment to innovation and scalability has made it a trusted partner for businesses navigating the complexities of global supply chains.

The Challenge

GEODIS’ Nashville facility needed a high-performing, flexible fulfillment system to handle a constantly changing product mix and thousands of daily orders from a variety of clients. Without direct visibility into client SKU changes or peak season projections, they required a solution that could seamlessly manage orders across distribution channels while scaling efficiently. The ongoing labor shortage further underscored the need to automate manual picking tasks, reducing strain on employees and improving productivity.

The Solution

GEODIS implemented the Exotec Skypod system into its operations so it could better serve the needs of its diverse customer base. This advanced automated storage and retrieval system uses autonomous robots to retrieve items from vertical racks, reducing the time and labor required for order picking. By integrating the Skypod® system with the client’s warehouse management system (WMS), GEODIS ensured real-time inventory visibility and dynamic order prioritization.

The Results

The implementation of the Skypod system delivered measurable improvements:

- Three ergonomic picking stations capable of processing 773 lines per hour with three employees.

- Access to all SKUs in the system within two minutes or less, enabling urgent order fulfillment for fast shipping.

- System installed on schedule in just seven months after contract signing.

- Double-deep storage with 30-foot-tall racks maximizes warehouse height for high-density storage.

- Flexible scalability allows for cost savings by renting additional robots and integrating them into the system within minutes to meet peak season demand.

By leveraging automation, GEODIS not only resolved immediate challenges but also future-proofed its operations for long-term growth. This case study demonstrates the transformative power of 3PL providers in combining innovative technology with operational expertise.

Why 3PL is on the Rise

Sustainability is rapidly reshaping the logistics industry, and 3PL providers are leading the charge toward greener supply chains. Many are investing in energy-efficient warehouses, optimized transportation routes, and alternative fuel vehicles to reduce environmental impact.

By adopting eco-friendly automation, waste reduction strategies, and carbon-conscious distribution models, 3PLs help businesses align with corporate sustainability goals while maintaining operational efficiency. These innovations not only minimize emissions and waste, but also future-proof supply chains against evolving environmental regulations.

For companies seeking to reduce their carbon footprint while optimizing logistics, partnering with a sustainability-focused 3PL is a strategic move toward long-term resilience and compliance.

3PL Trends to Watch

The 3PL industry is set to evolve further, driven by emerging technologies, shifting consumer demands, and the need for sustainable logistics. Here’s what lies ahead:

1. Increased Adoption of Automation and Robotics

Automation will continue to be a game-changer for 3PL providers. Advanced systems like AS/RS, robotic picking, and automated guided vehicles (AGVs) will become standard in fulfillment centers, enabling faster order processing and reducing operational costs. Robotics will also enhance flexibility, allowing 3PLs to scale operations during peak demand.

2. Artificial Intelligence for Predictive Analytics

AI will play a vital role in optimizing supply chain decision-making. From demand forecasting to dynamic inventory management, predictive analytics powered by AI will allow 3PLs to anticipate challenges and improve operational efficiency. Real-time data insights will help businesses reduce waste, improve delivery accuracy, and respond to disruptions more effectively.

3. Growth of Sustainable Logistics

Sustainability will remain a key priority for 3PL providers as businesses aim to reduce their carbon footprints. Expect to see greater adoption of renewable energy sources, such as solar-powered warehouses, and an increase in the use of electric vehicles (EVs) for transportation. Additionally, sustainable packaging and reverse logistics will gain more traction, ensuring that supply chains are greener at every step.

4. Expansion of Micro-Fulfillment Centers

To meet the growing demand for same-day and next-day deliveries, 3PLs will increasingly invest in micro-fulfillment centers located near urban hubs. These compact facilities will shorten delivery times, reduce transportation costs, and provide a more localized approach to inventory management.

5. Enhanced Omnichannel Capabilities

With consumer expectations shifting toward seamless shopping experiences, 3PLs will expand their omnichannel capabilities. This includes integrating online and offline inventory, improving reverse logistics for easy returns, and providing real-time visibility into the entire supply chain.

6. Integration of Blockchain Technology

Blockchain technology has the potential to revolutionize supply chain transparency and security. 3PL providers may leverage blockchain to enhance traceability, reduce fraud, and streamline compliance with international regulations.

7. Customization and Personalization

As businesses seek more tailored logistics solutions, many 3PLs will focus on providing customizable services. From custom packaging and kitting to personalized delivery options, 3PLs will enable businesses to create unique experiences for their customers.

Shaping the Future of Logistics with 3PL Providers

As the demand for speed, flexibility, and sustainability grows, 3PL providers will continue to be instrumental in offering the expertise and infrastructure businesses need to thrive. Whether you’re looking to streamline operations, scale with demand, or future-proof your logistics strategy, partnering with a 3PL ensures your supply chain is equipped to meet the challenges and opportunities of tomorrow.

The world’s top 3PL providers, including GEODIS, rely on the Skypod system to enhance warehouse efficiency, scalability, and responsiveness to shifting demand. Our advanced automation solutions optimize storage, streamline order fulfillment, and help 3PLs meet the growing challenges of modern logistics.

Featured In

Share

Insights

-

April 15, 2025Top Warehouse Trends for 2025: Future of Automation

-

April 9, 2025Material Handling: Basics, Benefits, & Automation

-

April 4, 2025Complete Guide to Pick-and-Place Automation

News

-

March 24, 2025Exotec Showcases Next-Gen Skypod System at ProMat 2025

-

March 17, 2025Exotec Announces Partnership with Oxford Industries to Implement Next Generation Skypod System in New Multi-Brand Distribution Center

-

February 27, 2025Colruyt‘s Collect&Go continues its automation journey with Exotec

Events

-

April 16, 2025 | Grand Rapids, MIExotour: Grand Rapids, MI

-

May 7, 2025Exodinner: Indianapolis, IN

-

May 22, 2025 | Cincinnati, OHExotour: Cincinnati, OH