In the healthcare industry, supply chain management is a delicate balance of efficiency, precision, and compliance. The ability to deliver medical supplies, pharmaceuticals, and equipment on time can directly affect patient care and outcomes. Supply chain automation is becoming a crucial factor in achieving this balance, especially as the demand for healthcare services increases and regulatory requirements become more stringent. Automation not only enhances operational efficiency but also ensures accuracy, safety, and compliance—making it a critical component of modern healthcare fulfillment strategies.

As healthcare providers face increasing demands, warehouse automation is transforming the way medical products and supplies are stored, tracked, and delivered. Whether it’s managing pharmaceutical inventories or distributing medical devices, automated solutions can significantly reduce human error, lower costs, and enhance overall speed and throughput.

The Impact of Automation on Healthcare Fulfillment

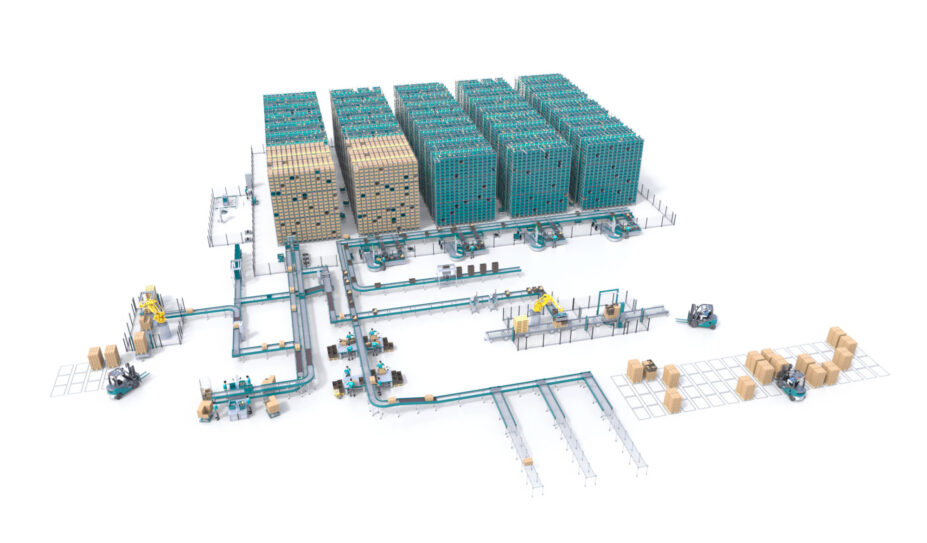

Traditional warehouse fulfillment processes in healthcare have long relied on manual labor. Workers would be responsible for picking, packing, and shipping a wide range of items, often leading to inefficiencies, inaccuracies, and higher labor costs. In healthcare, these inefficiencies can be particularly costly, both in financial terms and in terms of patient outcomes. With the rapid adoption of automation, healthcare warehouses are beginning to rely on more advanced robotics, such as Autonomous Mobile Robots (AMRs), Automated Storage and Retrieval Systems (ASRS), and artificial intelligence-driven inventory management tools. Their impacts include:

1. Enhanced Accuracy and Speed

In healthcare, errors can have life-or-death consequences, especially when it comes to the delivery of critical supplies like medication, surgical tools, or diagnostic equipment. Automation addresses these challenges by reducing human error in critical processes. Systems like Automated Mobile Robots (AMRs) and ASRS use sensors, cameras, and advanced algorithms to ensure accurate handling throughout the fulfillment process. Paired with technologies like RFID, pick-to-light, and barcode scanners, inventory can be tracked using unique serial numbers, providing visibility throughout the process. This level of tracking is especially vital for medical products with limited shelf life, ensuring strict adherence to the first-in-first-out (FIFO) method to avoid expired items.

In addition, healthcare operations should prioritize automation systems with strong operator safeguards to further enhance accuracy. These systems should enable individual access limits, track each item transfer made by operators, and send alerts if unapproved movement is detected, ensuring tight control over inventory and reducing the risk of mishandling.

2. Maximizing Space Utilization

Optimizing space is essential in any warehouse, but in healthcare, where the range of products is vast, it becomes even more critical. Advanced automation systems like ASRS maximize both vertical and horizontal space by using tall storage racks and narrow aisles for robots to traverse. However, how inventory is stored plays a key role in retrieval times. For example, mobile ASRS systems, such as the Exotec® Skypod® system, store inventory randomly throughout the system to prevent bottlenecks caused by high-demand items being clustered in the same area. This approach also eliminates the need for digging or shuffling bins, unlike cube-based ASRS systems, allowing all inventory to be retrieved within two minutes. As a result, healthcare facilities can handle larger inventories without expanding their physical footprint, reducing real estate costs and improving operational efficiency.

3. Operating in Challenging Environments

Robotic systems are ideal for cold storage in healthcare, efficiently managing temperature-sensitive products without exposing workers to harsh conditions. These systems prevent human handling of potentially dangerous items and can adjust for fragile products to avoid damage. Advanced software allows precise item arrangement in cartons—for example, placing heavier items on the bottom and fragile ones on top. With advanced sensors and smart algorithms, robotic automation ensures careful handling, fast fulfillment, and regulatory compliance.

4. Improving Labor Efficiency

Labor shortages and rising costs continue to challenge the healthcare industry, especially in warehouse management. Manual labor often results in inefficiencies and increased errors, making it difficult to scale operations. Automation offers a solution by handling repetitive, time-consuming tasks like picking, packing, and transporting goods, improving efficiency and reducing errors. This allows the workforce to focus on more complex tasks, such as managing inventory, ensuring quality control, and overseeing operations. The result is not only a more efficient workforce but also improved job satisfaction, as workers are relieved from monotonous and physically demanding tasks.

5. Data-Driven Decision Making

The integration of Warehouse Management Systems (WMS) and Internet of Things (IoT) technology is transforming healthcare fulfillment by enabling smarter, more efficient warehouse operations. IoT devices, such as sensors, RFID tags, and automated trackers, collect real-time data on equipment usage, inventory movement, and even environmental conditions. This data is then analyzed by the WMS, allowing for more informed decision-making and greater operational control.

For example, IoT devices continuously track the movement of products and equipment while the WMS processes this information to generate actionable insights. Managers can use these insights to optimize processes, improve employee productivity, and reduce operational costs. Additionally, this real-time data integration enables better tracking, enhanced automation, and precise inventory management, ensuring that healthcare warehouses operate at peak efficiency.

By working together, IoT and WMS create a powerful system that enhances visibility, improves forecasting, and streamlines decision-making, ultimately helping healthcare facilities operate more effectively.

Choosing the Right Automation Partner for Your Healthcare Warehouse

Implementing automation is not just about choosing the right technology—it’s about finding the right partner who understands the unique demands of the healthcare industry. Here are some key considerations when selecting an automation partner for your healthcare warehouse:

1. Scalability and Flexibility

In healthcare, demand can fluctuate dramatically due to factors like seasonal trends, product launches, or public health emergencies. As a result, your automation solution needs to be highly scalable, with the ability to adjust throughput and storage capacity independently. This prevents overinvestment in one area while scaling the other.

Advanced scalability also allows for innovative options, such as renting additional robots to meet peak demand, ensuring your system can handle surges without permanent infrastructure changes. Furthermore, a truly flexible system can service multiple channels—e-commerce, wholesale, and store replenishment—within a single platform, streamlining omnichannel operations and boosting efficiency.

Lastly, a robust automation system must seamlessly adapt to demand fluctuations across a wide variety of products. The Skypod system can retrieve all SKUs in two minutes or less, regardless of where it is stored within the system, ensuring your healthcare facility remains agile even during peak demand periods.

2. Integrated Inventory Management

A centralized, real-time inventory management system is essential for efficient healthcare fulfillment. Automated systems should seamlessly integrate with your existing Warehouse Management System (WMS), Enterprise Resource Planning (ERP) software, or other platforms. This allows for real-time visibility into stock levels, expiration dates, and regulatory requirements, helping prevent issues like stockouts, overstocks, and non-compliance.

3. Proven Expertise in Healthcare

Automating a healthcare warehouse requires an understanding of the industry’s regulatory landscape, product handling sensitivities, and the importance of accuracy. Look for automation partners with a proven track record in the healthcare sector. Their experience will be invaluable in navigating complex compliance requirements and ensuring that products are handled and delivered with precision.

4. Reliability and Robust Support

Reliability is essential when delivering medical devices, prescriptions, and other critical healthcare products. You need a system that ensures life-saving items reach their destinations on time, every time. A trusted automation partner provides guaranteed system performance and a robust support team dedicated to keeping your operational systems running smoothly, ensuring your healthcare supply chain meets its critical demands.

Revolutionizing Healthcare Fulfillment with Automation

The healthcare industry is undergoing rapid transformation, and automation is at the forefront of this shift. By improving accuracy, efficiency, and scalability, automation ensures that healthcare providers can meet the growing demands of the industry while maintaining compliance and reducing operational costs.

As you consider the future of your healthcare fulfillment, take a virtual tour of the Skypod system to see how advanced warehouse automation can revolutionize your processes and help you stay ahead in an increasingly dynamic industry.

Share

Insights

-

November 24, 2025The Right Mix of People and Robotics Wins Peak Season

-

November 13, 2025Warehouse Worker Sentiment: Understanding the Impact of Automation on Retention and Satisfaction

-

August 5, 2025Value Chain vs. Supply Chain: What's the Difference?

News

-

November 13, 2025Nearly Half of Warehouse Workers Receive Raises Because of Warehouse Automation

-

November 4, 2025Exotec bolsters its leadership team with the appointments of a Chief People Officer and EVP of Finance

-

October 15, 2025Exotec Celebrates 10 Years of Innovation: Driving A New Era of Warehouse Technology

Events

-

February 9, 2026 | Las VegasManifest 2026

-

April 13, 2026 | AtlantaMODEX 2026