Picking Workstations for Your Warehouse

Experience the future of warehouse automation with Skypod® Workstations. Designed for precision and performance, each Workstation supports order fulfillment at speeds of up to 600 bins per hour. With advanced features like semi-finished order handling and ergonomic design, the Skypod Workstation boosts productivity, reduces errors, and adapts to your evolving needs.

Superior Performance

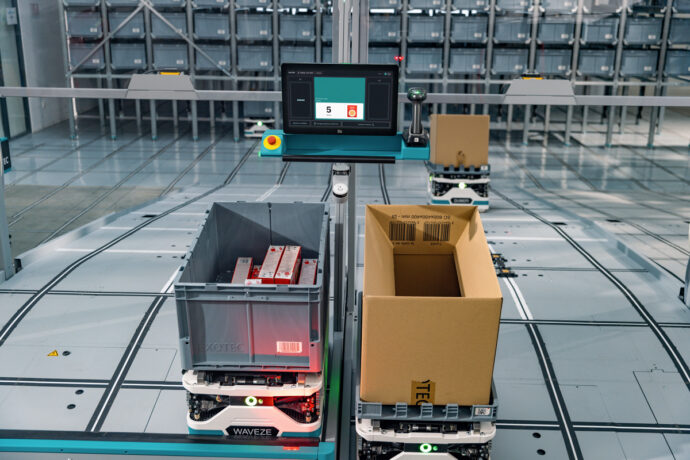

Enhance order preparation and speed by picking up to 600 bins per hour at each Workstation. Streamlining order fulfillment, the Workstation allows operators to pick and pack directly on the robot. This design enables handling single items instead of entire bins or boxes, significantly improving accuracy. Plus, integrated weight scales measure bin payloads and verify quantities, allowing for early robot departure and ensuring more orders are processed faster and more accurately.

Unique Design

The adjustable Workstation height adapts to any operator, enhancing comfort and reducing fatigue. Since operators only handle single items, the workload is lighter, and the one-to-one picking system eliminates the need for lifting, pulling, or walking to collect items. Intuitive HMI screens make training quick and easy, allowing new hires to be fully operational in minutes.

Pick-and-Pack

At Exotec®, pick-and-pack involves selecting items from inventory based on customer orders and immediately packaging them into shipping containers at the Workstation without needing specific equipment. The innovative design of the Workstation enhances efficiency by removing redundant steps, reduces handling time by allowing picking and packing directly on the robot, and ensures faster order fulfillment.

We Adapt to Your Needs

At Exotec®, we understand that every warehouse has unique needs. Our Skypod® system is designed to adapt and support a variety of operational requirements. Whether you need specialized configurations or custom solutions for your picking stations, our flexible system can be tailored to streamline your processes and enhance efficiency. Our Workstation easily connects to any external order preparation equipment, such as conveyors, put walls, and AMRs, ensuring your entire warehouse operations run smoothly.

Technical Specifications

| Characteristic | Specification |

|---|---|

| Source Containers Presentation Throughput | Up to 600 container/h |

| Ergonomics | Dynamic height adjustment of +/- 10 cm (+/- 4 in) |

| Combo & Semi-Finished | Yes |

| Early Departure | Yes, triggered by weight detection of last picked article |

| Customizable Station Screen | Yes, ability to add pop-up windows (e.g. instructions for operator) and/or a custom action button |

| Ability to Charge Robots | Yes |

| Buffering the Destination Containers | Yes |

Industry Insights

Frequently Asked Questions

What are automated picking stations?

Automated picking stations are specialized workstations within a warehouse that facilitate the automated retrieval and presentation of inventory items to operators for order fulfillment. These stations are a key component of Automated Storage and Retrieval Systems (ASRS), using advanced technology to streamline the picking process, reduce manual labor, and enhance overall efficiency in warehouse operations.

What are the benefits of using automated picking workstations in warehouses?

Automated picking workstations in warehouses offer numerous benefits, including:

Increased Efficiency: Automated systems can significantly speed up order fulfillment by quickly retrieving and presenting items to operators.

Enhanced Accuracy: Automated picking reduces the likelihood of human error, ensuring more accurate order fulfillment.

Improved Ergonomics: These workstations are designed to minimize physical strain on operators, improving comfort and reducing the risk of injury.

Ease of Use: Modern automated picking workstations feature intuitive interfaces that facilitate quick learning and immediate use, improving overall productivity.

How do ergonomic designs improve picking station efficiency?

Ergonomic designs improve picking station efficiency by:

Reducing Operator Fatigue: Adjustable station heights ensure that workstations can be set to the most comfortable level for each operator, reducing strain and fatigue.

Enhancing Comfort: Ergonomic layouts allow operators to quickly pick items from one bin to one fulfillment container, minimizing unnecessary movements and improving workflow efficiency.

Boosting Productivity: Comfortable and user-friendly workstations help maintain high productivity levels throughout shifts, as operators can work more efficiently with reduced need for walking long distances.

What tools are utilized by operators at the stations?

Operators at the Workstation use a variety of tools to enhance their efficiency and accuracy, including:

Intuitive HMI Screens: Customizable and easy-to-use screens and dashboards for quick learning and immediate use.

Integrated Weight Scales: To ensure precise picking and faster robot cycles.

Ergonomic Features: Adjustable station heights and user-friendly layouts for optimal comfort and efficiency, which also help to reduce operator fatigue.

Pick-and-Pack Capabilities: The ability to perform pick-and-pack operations directly at the Workstation without additional equipment, streamlining the order fulfillment process.

How many orders can the Workstation handle?

Exotec’s Workstation can present up to 600 inventory bins per hour, allowing operators to prepare multiple orders simultaneously. This high throughput capability makes Exotec’s Workstation an efficient and powerful component of automated order picking systems, capable of handling large orders with precision and speed.

Connect with Us

Eager to discover how you can easily and efficiently fulfill many orders within our Skypod® system? Contact us today to learn more about our advanced warehouse Workstations and how they can optimize your warehouse operations.