Rapid Responsiveness

Achieve faster reactivity to changing demands and operational needs.

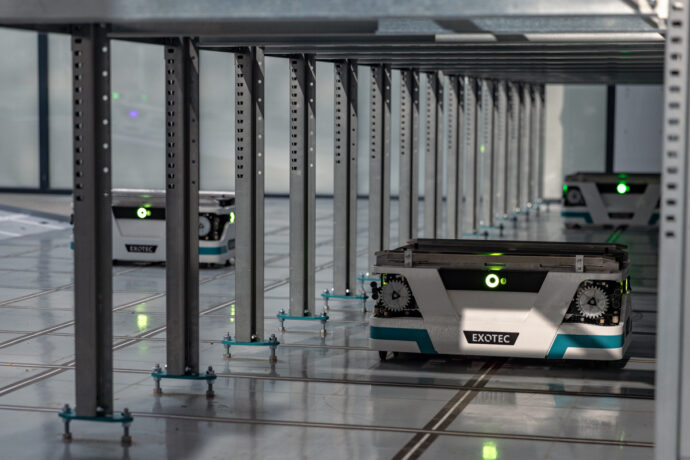

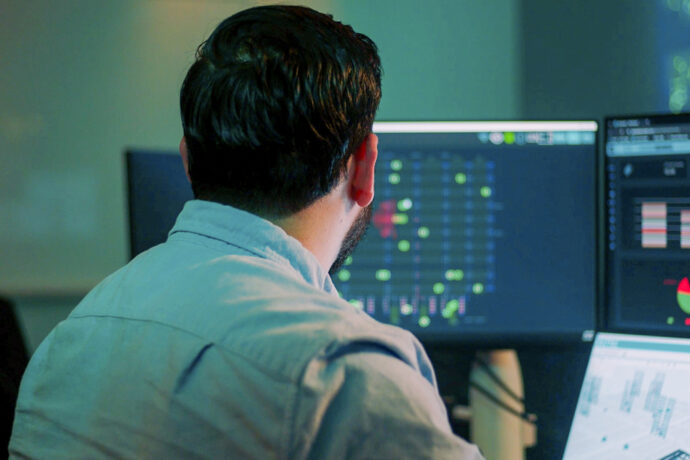

Our AS/RS solutions are standard yet customizable to meet your business needs. Scalable and adaptable, they grow with your operations. With Deepsky® software, access real-time inventory data and valuable operational insights to stay ahead.

Achieve faster reactivity to changing demands and operational needs.

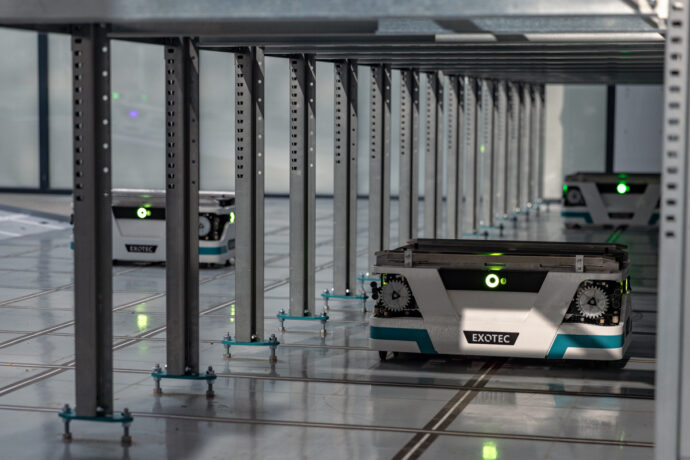

Benefit from better density for optimal use of warehouse space.

Improve operational efficiency across all warehouse processes.

Ensure improved accuracy in inventory management and order fulfillment.

Enjoy the flexibility of seamlessly handling peak periods and seasonal products.

Trust in performance that Exotec contractually guarantees.

Ready to transform your warehouse operations? Contact us today to learn more about Skypod® system.