Order picking is the backbone of warehouse operations, where items are selected from their storage locations to fulfill customer orders. The goal of order picking is to accurately assemble the items requested in each order while optimizing efficiency to meet customer demand within specified timeframes.

Case Picking vs. Piece Picking

Case picking and piece picking are two distinct order picking methods utilized in warehouse operations.

Case Picking

- Involves handling cases containing multiple items, usually of the same SKU, for shipment

- Efficient for high-volume orders with relatively low variety of SKUs

- Faster and requires less labor than piece picking for bulk orders due to fewer handling steps

- Typically utilized for bulk store replenishment or wholesale orders

Piece Picking

- Involves selecting individual items or units from the warehouse inventory to fulfill orders

- Commonly used for orders that consist of a variety of products or small quantities of each item

- Piece picking is more labor-intensive and time-consuming compared to case picking, especially in warehouses with a large number of SKUs.

- Suitable for e-commerce or retail operations where orders are diverse and may contain only a few items each

Additional Order Picking Methods

There are several key order picking methods, each designed to optimize efficiency and productivity based on factors such as warehouse layout, order volume, and item characteristics. Here are some of the most common order picking methods:

Single Order Picking

Single order picking, where each order is handled individually by a single picker, is best suited for warehouses with low to moderate order volumes or diverse item ranges. It offers a high degree of flexibility but potentially less efficiency for larger volumes.

Batch Picking

Batch picking involves a single picker picking multiple orders simultaneously, typically grouped based on factors like item proximity or priority, which improves efficiency by minimizing travel time. This method is particularly suited for warehouses with moderate to high order volumes and similar item characteristics across orders.

Zone Picking

In zone picking, the warehouse is divided into zones with pickers assigned accordingly. Items from each zone are consolidated centrally after picking, making it efficient for large warehouses with high order volumes by reducing each picker’s travel time.

Wave Picking

Wave picking combines elements of batch and zone picking, where orders are grouped into waves, each containing multiple orders picked simultaneously. Pickers may be assigned specific zones to pick items for orders within their designated wave, optimizing efficiency through batched orders and zone-specific picking strategies.

Factors to Consider When Choosing an Order Picking Method

Choosing the appropriate picking method is crucial for optimizing warehouse operations. Here are key priorities to consider when selecting a picking method.

- Flexibility and Scalability: Prioritize methods that offer flexibility to adapt to changing demand and scalability to accommodate future growth.

- Training: Consider the skill level required for pickers and the time and resources needed for training. Prioritize safety training to ensure adherence to proper protocols, and provide comprehensive instruction on any technology involved in the process. Implement ongoing training programs to support continuous learning and adaptation to changes in the picking process.

- Integration with Other Processes: Ensure that the chosen picking method integrates smoothly with other warehouse processes, such as replenishment, packing, and shipping.

- Software Integration: When integrating new technology, prioritize compatibility and integration capabilities. REST-based APIs offer a flexible and efficient way to connect new automation systems with existing Warehouse Management Systems (WMS) or Enterprise Resource Planning (ERP) systems.

From Manual to Automated Order Picking

The chart below from Research Gate highlights the importance of warehouse automation for order picking, showing that picking alone accounts for over 35% of total warehouse activity costs in the US.

Warehouse activities as a percentage of warehouse costs

The distinction between manual and automated order picking hinges on the degree of human involvement and technological integration. In manual picking, workers physically locate and collect items for orders, relying heavily on human judgment and labor.

Several automated order picking systems complement manual picking, marking a significant advancement in efficiency and precision compared to fully manual operations. Despite their ability to be quickly implemented into warehouse operations and notably reduce error rates, they still require considerable manual labor investment. These systems include:

- Barcode Scanners: Utilizing light beams to read barcode information, these scanners enable precise identification of items for inventory management and order fulfillment

- Pick-to-Light Systems: Equipped with lights and displays installed at storage locations, pick-to-light systems illuminate the items that need to be picked for a specific order, guiding workers precisely through the picking process

- Voice-Directed Systems: Through wireless headsets or handheld devices, these systems deliver spoken instructions to pickers, directing them to ordered items in the warehouse

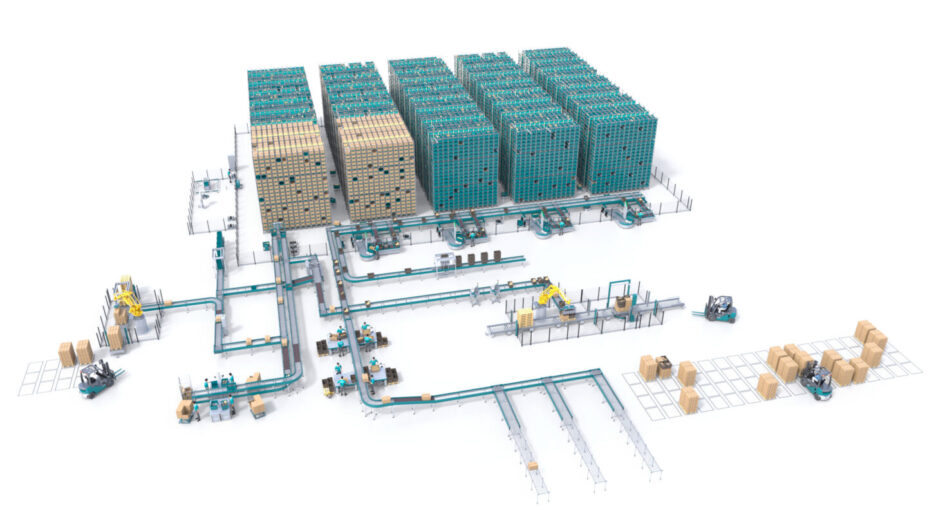

At the pinnacle of automated order picking are Automated Storage and Retrieval Systems (ASRS). These systems use machines or robots to store and retrieve items, bringing them to picking stations. This automation reduces errors while delivering the highest levels of throughput and storage capacity, setting it apart as a leading solution in warehouse efficiency.

The Optimal Order Picking Solution

The Exotec Skypod system is a mobile ASRS offering the optimal mix of performance and flexibility. It utilizes advanced robotics to store goods in high-density racks and deliver them to ergonomic picking stations. With up to 5X throughput compared to manual operations and the ability to retrieve any item in the system within two minutes, it meets the demands of fast shipping for all inventory.

Featured In

Share

Insights

-

April 15,2025Top Warehouse Trends for 2025: Future of Automation

-

April 9,2025Material Handling: Basics, Benefits, & Automation

-

April 4,2025Complete Guide to Pick-and-Place Automation

News

-

April 1,2025E.Leclerc Ville-la-Grand optimises its Drive-thru with the Exotec robotic solution

-

February 27,2025Colruyt‘s Collect&Go continues its automation journey with Exotec

-

February 6,2025Exotec Launches Next Generation of Skypod System, an All-in-One Robot-Based AS/RS, that Addresses the Majority of Processes Within a Warehouse

Events

-

May 19,2025 | BarcelonaGartner, the reference for logistics trade fairs in Europe

-

June 12,2025 | LondonRetail Gazette Efficiency Debate, in London

Ready to transform your warehouse?

Let us show you how we can take your order preparation to the next level.