Case picking is an integral process within warehouse operations, optimizing the process of handling large orders, typically for store replenishment and wholesale distribution. It involves handling cases containing multiple items, usually of the same SKU, for shipment. Technological advancements have greatly enhanced case picking as warehouse operations evolve, leading to increased efficiency and flexibility.

What is Case Picking Used For?

Case picking is best suited for handling bulk orders that require some customization but not enough to warrant piece picking (picking individual items). This method is ideal when items are pre-packaged in case quantities aligned with order needs.

Benefits of Case Picking

Implementing effective case-picking strategies significantly boosts warehouse operations in various ways:

- Enhanced Efficiency: Simplifies the shipping process by reducing handling steps, especially when shipping entire cases instead of individual pieces.

- Improved Order Accuracy: Lower potential for errors as picking entire cases involves fewer transactions compared to piece picking.

- Optimized Space Utilization: Requires less space than storing individual items, which may need additional shelving, whereas pallets consume more space.

- Reduced Manual Labor Costs: Eliminates the need to pick individual items, saving time and reducing labor costs.

- Increased Safety: Minimizes the use of heavy equipment like forklifts required for moving full pallets, enhancing safety within the warehouse environment.

Strategies for Improved Case Picking

Utilize Automation Technology: Leveraging automation technology greatly improves case-picking efficiency. Relatively simple tools like barcode scanners, which use light beams to read barcode data, enable precise identification of items for inventory management and order fulfillment. Pick-to-light systems provide visual cues, guiding workers quickly and accurately to the correct cases for picking or placement.

Optimize Warehouse Layout: Arrange the warehouse to minimize travel time, with high-demand items stored closer to picking stations and grouped by frequency of use or picking patterns. Similarly, regularly review and optimize slotting based on item demand, seasonality, or changes in inventory to ensure frequently picked items are easily accessible.

Continue Training: Provide ongoing training to staff on the latest systems, tools, and best practices to maintain high productivity and accuracy. Consider using Labor Management Systems (LMS) to track performance, optimize workforce deployment, and identify areas for improvement in case-picking operations.

Improve Ergonomics: Implement practices that ease the picking process for employees, such as adjustable workstations, ergonomic carts, and placing frequently picked items at waist height to reduce bending and lifting.

Reduce Strain: Rotate workers through different tasks to avoid repetitive strain injuries, use anti-fatigue mats and proper footwear to lessen the impact of standing, and offer training on safe lifting techniques to reduce injury risk.

Case Picking Methods

There are several key order case picking methods, each designed to boost efficiency based on warehouse layout, order volume, and item characteristics:

- Single Order Picking: Each order is handled individually, ideal for low to moderate volumes or diverse items, but less efficient for larger orders.

- Batch Picking: One picker handles multiple orders at once, grouped by factors like item proximity, reducing travel time and improving efficiency in moderate to high-volume warehouses.

- Zone Picking: Pickers are assigned to specific zones, and items are consolidated centrally, minimizing travel time in large, high-volume warehouses.

- Wave Picking: Combines batch and zone picking, where pickers work in specific zones on grouped orders, optimizing efficiency through a wave-based approach.

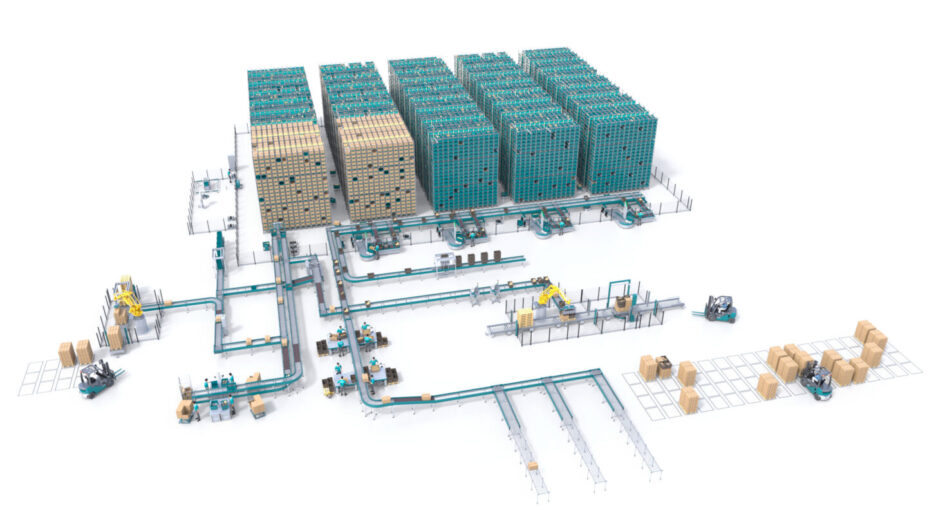

The Exotec Skypod system automates the entry and removal of cases from storage racks.

Manual vs. Automated Case Picking

Manual Case Picking: Manual case picking is a hands-on process where warehouse staff physically collect cases from shelves, racks, or pallets, often using carts or forklifts for assistance. After retrieval, workers consolidate these cases onto pallets or carts for further processing or direct shipping. The final step involves preparing the picked cases for dispatch, which includes labeling and wrapping the cases, ensuring they’re ready for loading onto delivery trucks.

Manual case picking poses several challenges for warehouse operations. It is labor-intensive, relying on physical exertion from workers to retrieve cases, leading to fatigue and potential injuries. There’s a risk of errors, as manual handling increases the likelihood of picking the wrong cases or quantities. Additionally, manual case picking is less efficient than automated methods, resulting in slower order processing times and higher operational costs.

Automated Case Picking: Automated case picking utilizes machines or robotics to retrieve and handle cases of products, reducing the need for manual labor. These systems improve efficiency, accuracy, and speed by automating the selection, transportation, and sorting of cases, making the fulfillment process faster, more accurate, and scalable for higher order volumes.

The Optimal Case Picking Solution

Manual case picking is suitable for low-volume orders but struggles with rising demand, leading to the adoption of Automated Storage and Retrieval Systems (ASRS) like the Exotec® Skypod® system, offering the optimal mix of performance and flexibility for case picking operations.

The system boosts throughput up to 5x compared to manual methods, with the ability to retrieve any case within two minutes. Its modular design adapts to varying throughput, storage, and industry needs, making it ideal for SKU adjustments or shifts from B2B to B2C, while easily scaling with business growth.

Take the Skypod system virtual tour to see how it can transform your warehouse.

Featured In

Share

Insights

-

April 15,2025Top Warehouse Trends for 2025: Future of Automation

-

April 9,2025Material Handling: Basics, Benefits, & Automation

-

April 4,2025Complete Guide to Pick-and-Place Automation

News

-

April 1,2025E.Leclerc Ville-la-Grand optimises its Drive-thru with the Exotec robotic solution

-

February 27,2025Colruyt‘s Collect&Go continues its automation journey with Exotec

-

February 6,2025Exotec Launches Next Generation of Skypod System, an All-in-One Robot-Based AS/RS, that Addresses the Majority of Processes Within a Warehouse

Events

-

May 19,2025 | BarcelonaGartner, the reference for logistics trade fairs in Europe

-

June 12,2025 | LondonRetail Gazette Efficiency Debate, in London

Ready to transform your warehouse?

Let us show you how we can take your order preparation to the next level.