Understanding our clients is at the top of our list of values. To that extent, we recently conducted a survey of 50+ supply chain professionals at the executive and operational levels to better understand their needs and concerns. Our aim was to be selective about industries and job titles, making sure we hear from the voices that matter. Our survey revealed a few interesting insights.

Warehouse Automation is No Longer Pie in the Sky

80% of warehouses today don’t have any form of automation. This is largely because, until recently, the price and availability of labor weren’t a huge issue. Automation was perceived as a lengthy and capital-intensive process that also required shutting down at least part of your warehouse during the deployment. This means that the majority of warehouse operators viewed automation as a long-term project that could get pushed out into the future by relying on short-term band-aid solutions like hiring seasonal workers.

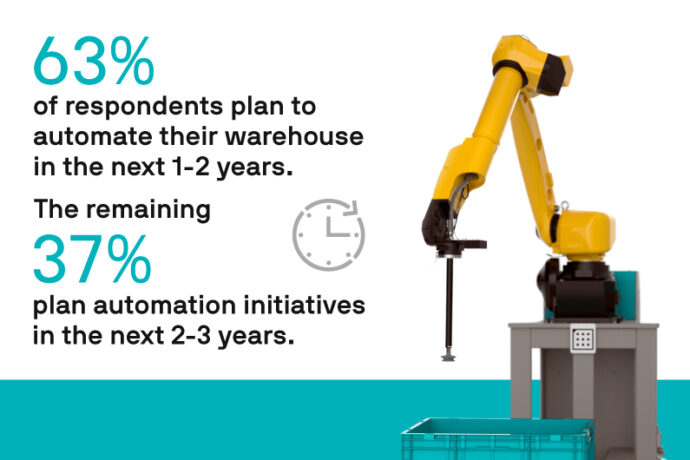

In recent years, this has changed. For a variety of demographic and socio-economic shifts, warehouse labor is scantily available and becoming more expensive. The traditional model that relied on the availability of seasonal labor is no longer tenable. This is forcing warehouse managers to rethink their approach and timelines. In our survey, 63% of the respondents had plans to automate their warehouse in the next 1-2 years with the remaining planning automation projects in the next 2 to 3 years. Automation is no longer a long-term project, but an immediate need that requires a concerted effort.

The Macroeconomic Environment is Driving the Adoption of Goods-to-Person Systems

There is a lot to be said about the seesawing nature of the macroeconomic environment. Between ever-present supply chain hurdles, rampant inflation, and seemingly inevitable recession, businesses are struggling to distill market signals and are unable to strategize for the future.

In the goods-to-person space though, it seems that the uncertain economic environment is actually driving the demand for the solution. Whether it’s the fears of rising prices or the inability to forecast labor availability, 78% of the respondents to our survey said they were likely or somewhat likely to invest in a goods-to-person system over the course of the next 2 years.

Warehouse Robotics is Eating the Warehouse Automation Market

If you look at the most recent entrants in the warehouse automation market, the vast majority of them offer robotic-based solutions. Unlike legacy automation solutions, such as shuttles and mini-loads that rely on heavy and complex machinery, the new solutions typically rely on autonomous mobile robots that move between static infrastructure to carry out required tasks.

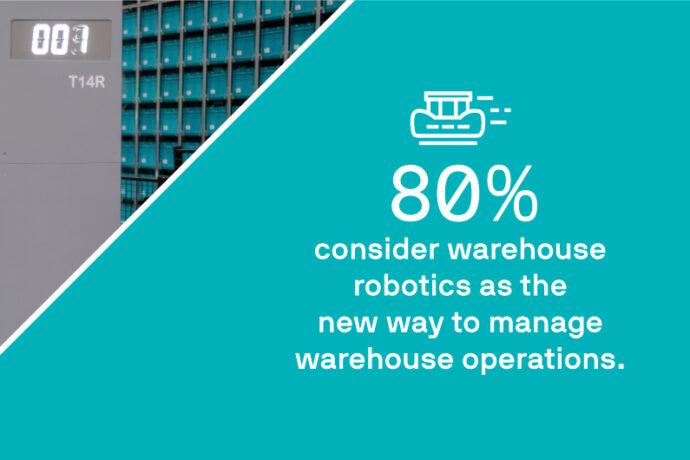

There is a good reason for it. Robotic solutions tend to be faster to install, offer a similar level of performance, and are much more flexible both in terms of scaling throughput and the range of tasks that they can accomplish. And it seems that people involved in purchasing decisions increasingly recognize it. Our survey found that 80% of respondents consider warehouse robotics as the new way to manage warehouse operations.

Ready to learn more about warehouse robotics? Fill out the form below to stay connected via our newsletter.

Ready to transform your warehouse?

Let us demonstrate how we can elevate your order preparation to the next level.

Featured In

Share

News

-

February 27,2025Colruyt‘s Collect&Go continues its automation journey with Exotec

-

February 6,2025Exotec Launches Next Generation of Skypod System, an All-in-One Robot-Based AS/RS, that Addresses the Majority of Processes Within a Warehouse

-

January 9,2025Exotec appoints new Project Operation Director to drive growth in Benelux

Events

-

May 19,2025 | BarcelonaGartner, the reference for logistics trade fairs in Europe

-

June 12,2025 | LondonRetail Gazette Efficiency Debate, in London

Ready to transform your warehouse?

Let us show you how we can take your order preparation to the next level.