Navigating the uncertainties and complexities of managing an apparel warehouse in today’s dynamic and competitive marketplace is challenging—and it won’t get any easier.

Apparel businesses are at a critical juncture where modernizing their warehouses is essential for growth. Read on for a quick overview of a few of the most pressing challenges in apparel warehousing and how leading brands are effectively addressing them with modern automated storage and retrieval systems (ASRS).

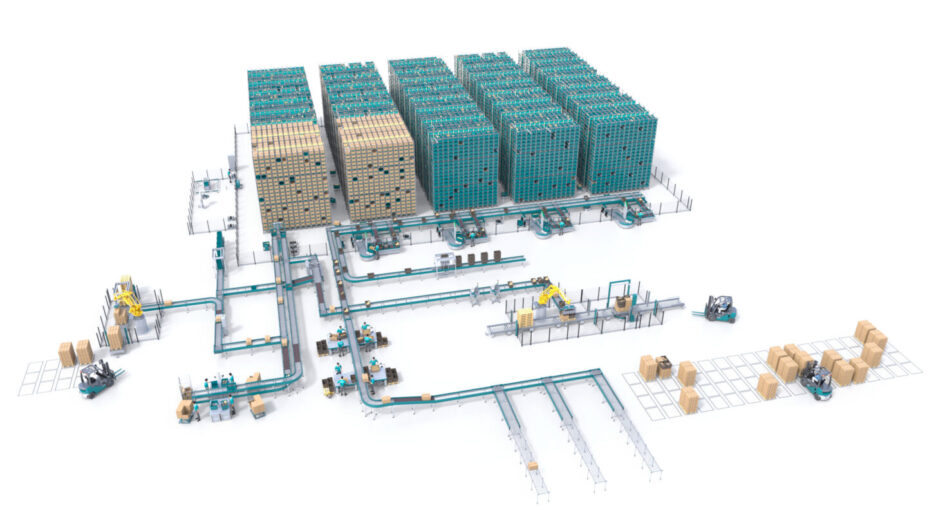

Here is a look at the Exotec Skypod system in action, a leading ASRS solution used by performance apparel retailer, Ariat.

Shifting Markets

After significant growth over the past few years, the apparel industry is now facing a sales slowdown. McKinsey reports a 0.9% decline in U.S. apparel sales in April 2024 with weakening consumer confidence and rising prices expected to further reduce spending. Additionally, many businesses are struggling with excess inventory from the previous sales boom. To address these challenges, leading businesses are adopting ASRS that utilize machinery or robotics to transport items efficiently between storage racks and picking stations.

For instance, the Exotec® Skypod system® has helped several multinational businesses like Ariat and Rediv become more efficient with their apparel order fulfillment. This system handles both B2B and B2C orders within a single platform, enhancing inventory consolidation and visibility. It’s simple, modular design—consisting of robots, storage racks, and picking stations—enables them to independently scale throughput and storage as the business grows and adapts to an unpredictable future.

Rising Returns

Retailers are facing significant challenges due to economic pressures affecting consumers and businesses. In response, many clothing retailers have launched extended sales and promotions, which have boosted sales but also led to a higher volume of returns. Statista reports that clothing was the most returned item in 2023, making up nearly 25% of returns.

To address reverse logistics, retailers need efficient systems for processing returns and reintegrating items into stock. They are prioritizing ASRS that enable system operators to efficiently scan items into mixed SKU bins, which are then automatically transported into storage. Efficient reverse logistics can determine whether a returned item is discarded or resold at full price, thus protecting profits in a challenging economic environment.

One of Exotec’s clients, a Fortune 500 retailer, utilized the Skypod system to enhance their reverse logistics, processing and storing over 450 lines per hour within a compact 3,800 ft² (353 m²) footprint. Subsequently, they installed an additional system for returns, capable of processing and storing more than 1,050 lines per hour from a 6,705 ft² (623 m²) footprint.

Rising e-Commerce Standards

The standards for quality service in e-commerce are rising, with customers demanding faster, low-cost shipping and exceptional accuracy. This is straining traditional warehouses. To meet these demands, many businesses are prioritizing automation that can increase throughput and enable the servicing of urgent order requests for all SKUs—a challenging task.

The Skypod system meets this challenge with the ability to increase throughput by up to five times compared to manual operations. It can retrieve any ordered SKU within two minutes, ensuring rapid order fulfillment and consistent accuracy with technologies like pick-to-light and put-to-light systems to guide operators.

For example, Rediv, a popular second-hand clothing retailer, utilized the Skypod system to quadruple their throughput. This enabled them to boost their shipping volume from 200,000 to 750,000 items per month.

Keeping Up with Labor

Let’s face it, warehouse jobs are undesirable, leading to high turnover. Modern ASRS streamline the most costly and time-intensive warehouse processes—storage and retrieval. This reduces dependence on manual labor and allows picking tasks to be shifted to value-added roles like quality control and custom packaging, enhancing efficiency and job satisfaction.

For instance, after implementing the Skypod system, Ariat successfully shifted 80% of their picking labor to more valuable roles. In 2022, when Ariat needed to expand throughput to accommodate growth, they seamlessly increased the number of robots in their system from 57 to 86 in under an hour, without incurring additional labor costs.

Take a Skypod System Virtual Tour

Take a virtual tour of our Skypod system and discover how it can equip your retail warehouse with the performance and flexibility needed to thrive into an unpredictable future.

Share

Insights

-

April 15,2025Top Warehouse Trends for 2025: Future of Automation

-

April 9,2025Material Handling: Basics, Benefits, & Automation

-

April 4,2025Complete Guide to Pick-and-Place Automation

News

-

April 1,2025E.Leclerc Ville-la-Grand optimises its Drive-thru with the Exotec robotic solution

-

February 27,2025Colruyt‘s Collect&Go continues its automation journey with Exotec

-

February 6,2025Exotec Launches Next Generation of Skypod System, an All-in-One Robot-Based AS/RS, that Addresses the Majority of Processes Within a Warehouse

Events

-

May 19,2025 | BarcelonaGartner, the reference for logistics trade fairs in Europe

-

June 12,2025 | LondonRetail Gazette Efficiency Debate, in London

Ready to transform your warehouse?

Let us show you how we can take your order preparation to the next level.