Labor shortages are no longer a temporary hurdle but a long-term challenge reshaping supply chains worldwide. Robotics has emerged as the foremost solution for industries like warehousing and fulfillment that are looking to increase operational efficiency and reduce costs.

This has fueled discussions about potential harm to human labor. But rather than simply asking, “Will robots take these jobs?” we should explore how people can collaborate with robotics to make work easier, safer, more efficient, and create new opportunities for employees.

Ongoing Labor Shortages and Challenges

Warehouses are under constant pressure to meet rising consumer demands for things like faster order fulfillment, broader product selection, and customized orders, all with perfect accuracy. Add the complexities of peak season sales, and the challenge becomes even greater.

In manually operated facilities, workers must tackle these demands while dealing with tough conditions like excessive walking, heavy lifting, and working near dangerous machinery. It’s no surprise that many warehouse operations struggle to hire and retain enough workers to keep things running smoothly. According to a 2024 report from Instawork, 40% of respondents say they still don’t have enough warehouse workers to meet demand.

These ongoing labor challenges highlight the need for innovative solutions, such as robotic automation, to fill workforce gaps and ensure operational efficiency. By reducing the reliance on manual labor, warehouses can not only meet rising consumer expectations but also create safer and more sustainable operations to handle future growth.

Jobs Perfectly Suited for Robotics

In warehousing, some tasks are simply better suited for robots—especially order picking and sorting. These are among the most time-consuming and physically demanding tasks in a warehouse. The average picker often walks over 10 miles a day, repeatedly bending and lifting heavy items. This work can quickly become exhausting and doesn’t require much creativity, just a lot of time and energy. The more physically challenging and repetitive the task is, the less humans tend to want to do it—making it ideal for robots to handle.

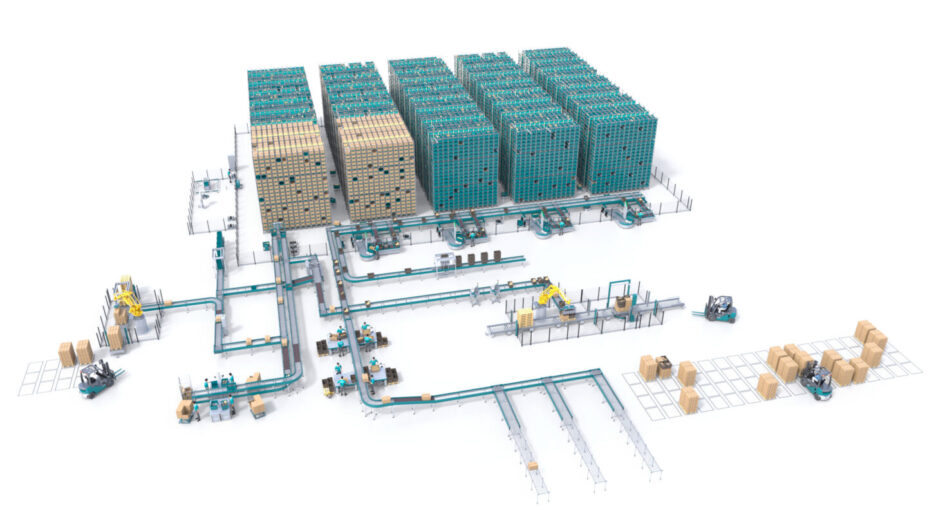

To address this, many businesses are turning to automation, specifically robotic systems such as Automated Storage and Retrieval Systems (ASRS) and Autonomous Mobile Robots (AMR) to streamline operations and improve efficiency. These systems use robots to transport goods between storage racks and picking stations, where operators can quickly and accurately process orders. The result is minimal order errors, faster fulfillment, and improved customer satisfaction.

Jobs Created by Robotics

Robotics is transforming workplaces by alleviating the physical strain of repetitive tasks and empowering employees to take on higher-value roles. With robots managing labor-intensive duties, employees can shift their focus to strategic priorities such as:

- Process Improvement: Robotics has enabled businesses to allocate more employees to developing and implementing strategies that streamline operations, reduce waste, and boost productivity.

- Data Management and Analysis: Automation generates vast amounts of data, which must be analyzed to optimize performance. New jobs have emerged in data analytics, improving operational efficiency and streamlining workflows.

- Technical Training: As companies embrace automation, the need for employees trained in robotics management and maintenance continues to grow.

- Order Customization: The demand for personalized goods and packaging tailored to specific customer orders or branding is steadily increasing.

- Quality Assurance and Control: Inspecting products for defects and ensuring compliance with customer and regulatory standards is essential for successful operations, and more employees are often needed to manage this task effectively.

This shift in the labor market reflects how technology is changing the types of jobs available rather than eliminating them.

Economic Impacts of Robotics

Robotic automation combines speed, density, and precision to improve operational performance and reduce costs. It also gives businesses a competitive edge by enhancing service quality, helping them attract and retain more customers.

Boosting Efficiency

Robotics significantly enhance throughput, exemplified by the Exotec® Skypod® system—a mobile ASRS that boosts throughput by up to 5x compared to manual operations. Its robots can retrieve any SKU from storage in under two minutes, enabling warehouses to meet growing consumer demands for faster delivery times. This efficiency is especially critical during peak seasons when operational speed is paramount. The result? Businesses process more orders accurately, boosting customer satisfaction and loyalty.

Maximizing Space

Many robotic systems use tall storage racks that go much higher than those in manual operations. Since robots handle the work, there’s no safety concern with accessing goods at greater heights. This allows warehouses to maximize vertical space, increasing storage density. As a result, operations can fit into smaller warehouses—an important advantage given the rising cost of real estate.

Reducing Errors

Human errors in picking can lead to costly returns and dissatisfied customers. Consider this: order picking accuracy of 99%, for 1,000,000 orders can translate to 10,000 unhappy customers. This can result in significant financial losses, damage to your brand reputation, and potential loss of customer loyalty. Robotic automation eliminates guesswork, ensuring precise and reliable order fulfillment.

Reducing Reliance on Manual Labor

Robotic automation reduces the need for manual labor by handling repetitive tasks like picking and packing orders, helping businesses overcome labor shortages and improve efficiency. It also enhances workplace safety and allows employees to focus on higher-value tasks like quality control and order customization that improves customer service.

Making Warehouse Work Safer

Safety is another critical area where automation transforms the workplace. Robots take on high-risk jobs, such as handling heavy loads and hazardous materials or operating in high-traffic areas. This significantly reduces common injuries like back strain and repetitive motion disorders. By redesigning workflows around robotics, employees can avoid awkward or taxing movements, promoting better ergonomics and long-term health.

Automation also allows robots to operate in environments that are too dangerous for humans—extreme temperatures, elevated storage areas, or other hazardous conditions—minimizing exposure to risks. When humans and robots collaborate effectively, the workplace becomes safer, more efficient, and more empowering. Employees feel valued and supported, resulting in higher morale, better productivity, and a stronger sense of purpose.

Reimagining the Future of Work with Robotics

As labor shortages persist and consumer expectations rise, robotic automation is proving essential for modern warehousing. By handling time-consuming and physically taxing tasks, robots allow employees to shift their focus to roles that drive innovation and operational improvements. This partnership enhances efficiency, reduces errors, and ensures safer working conditions. See how solutions like the Exotec Skypod system are transforming warehouse operations.

Featured In

Share

Insights

-

April 9, 2025Material Handling: Basics, Benefits, & Automation

-

April 4, 2025Complete Guide to Pick-and-Place Automation

-

February 20, 2025What Is 3PL? Understanding the Role of Third-Party Logistics

News

-

March 24, 2025Exotec Showcases Next-Gen Skypod System at ProMat 2025

-

March 17, 2025Exotec Announces Partnership with Oxford Industries to Implement Next Generation Skypod System in New Multi-Brand Distribution Center

-

February 27, 2025Colruyt‘s Collect&Go continues its automation journey with Exotec

Events

-

April 16, 2025 | Grand Rapids, MIExotour: Grand Rapids, MI

-

May 7, 2025Exodinner: Indianapolis, IN

-

May 22, 2025 | Cincinnati, OHExotour: Cincinnati, OH