Accuracy is essential in logistics. However, picking errors remain a common and costly problem, leading to delays, higher costs, and unhappy customers. Technologies like Automated Mobile Robots (AMRs) and Automated Storage and Retrieval Systems (ASRS) are changing how warehouses operate, drastically reducing errors. This article covers practical strategies to reduce picking errors in your warehouse, improving accuracy and customer satisfaction.

What is Order Picking?

Order picking is a crucial step in the supply chain process, where products are retrieved from storage to fulfill customer orders. It involves identifying, collecting, and preparing items for shipping. Despite its importance, order picking is often prone to errors. Consider this: out of 1,000,000 orders, if the average order picking accuracy is 99.4%, it means that 6,000 orders could be wrong. That translates to 6,000 unhappy customers. These figures highlight the importance of order accuracy.

Mistakes such as picking the wrong item, incorrect quantity, or even omitting an item can have severe consequences for businesses, leading to customer complaints, returns, and loss of reputation. Several factors contribute to picking errors, including human error, poor warehouse layout, and inefficient inventory management. Understanding these factors and implementing the right strategies can drastically reduce errors and improve efficiency.

Types of Order Picking

Understanding the different types of order picking is important for selecting the most appropriate method for your warehouse, as some methods are more prone to errors than others.

- Single-Order Picking: In single-order picking, a worker picks one order at a time. While this method is straightforward, it can be time-consuming and is typically used in small operations.

- Batch Picking: Batch picking involves picking items for multiple orders simultaneously. This method is more efficient than single-order picking but requires careful coordination to prevent items from being mixed up between orders.

- Zone Picking: In zone picking, the warehouse is divided into zones, and workers are assigned to pick items only within their designated zone. Afterward, they either pass the items to the next zone or send them to a packing area for consolidation. This method reduces travel time and improves accuracy as workers become familiar with their area.

- Wave Picking: Wave picking is similar to batch picking but involves picking items for multiple orders during specific periods or “waves.” This method is often used in large warehouses with high order volumes. However, it requires sophisticated planning to pick and sort the correct items for each order.

- Automated Picking: Automated picking uses technologies like AMRs and ASRS to pick items with minimal human intervention. This method is the most accurate and efficient, as it reduces the number of steps for operators and gives them easy, error-proof prompts and tools.

Manual Picking vs Automated Picking

Manual picking relies on human labor, which, while flexible, is prone to errors, especially in high-volume operations. Automated picking, on the other hand, uses technology to enhance accuracy and speed.

| Aspect | Manual Picking | Automated Picking |

| Accuracy | Prone to human error, especially during long shifts. | Highly accurate, utilizes real-time inventory tracking, provides operators with intuitive prompts, and machines that don’t suffer from fatigue. |

| Efficiency | Slower and adaptable but cannot match automated systems in large-scale operations. | Faster and consistent, can work 24/7, and handle high order volumes. |

| Cost | Lower upfront costs but higher long-term costs due to errors, returns, and slower processing. | High initial costs, but leads to long-term savings by reducing manual labor and minimizing errors. |

| Flexibility | Greater flexibility as human workers adapt to changes in order types or volumes. | Offer varying degrees of flexibility depending on the sophistication of the software. |

Ways to Optimize Order Picking

- Gather Employee Feedback: Routinely gather employee feedback from frontline workers, supervisors, and managers. Their insights can reveal pain points in current processes, such as bottlenecks or safety concerns, that aren’t always evident through metrics alone. Understanding the workforce’s perspective can highlight potential areas where automation can improve job satisfaction by reducing repetitive or physically demanding tasks.

- Coordinate Employee Training: Continue providing staff with ongoing training on the latest systems, tools, and best practices to maintain high productivity and accuracy. Consider using Labor Management Systems (LMS) to track performance and identify areas for improvement in picking operations.

- Improve Ergonomics: Implement practices like adjustable workstations, ergonomic carts, and placing frequently picked items at waist height to reduce bending and lifting. Reducing strain through worker rotation, anti-fatigue mats, proper footwear, and training on safe lifting techniques helps prevent injuries and keeps your workforce healthier and more productive.

- Optimize Warehouse Layout: A well-organized warehouse layout can significantly reduce the time it takes to pick items and the likelihood of errors. Grouping commonly picked items together, ensuring clear labeling, and minimizing travel distances between picking locations can improve efficiency and accuracy.

- Implement Barcode Scanning: Barcode scanning is a simple yet effective way to reduce picking errors. By scanning items at various stages of the picking process, workers can ensure they have selected the correct product. Integrating barcode scanning with warehouse management systems (WMS) also allows for real-time inventory updates, further reducing errors.

- Utilize Pick-to-Light Systems: Pick-to-light systems use light indicators to direct workers to the precise product location and quantity while also guiding them on where to place the items. These systems can drastically reduce mistakes, particularly in high-volume operations.

- Use Voice Picking Technology: Voice-picking technology provides workers with verbal instructions through headsets, guiding them to the correct picking location and confirming item selection. This hands-free approach speeds up the picking process and reduces the likelihood of errors by allowing workers to focus entirely on their tasks.

- Leverage Data Analytics: To get the best out of your data, start by making sure all your systems are on the same page. It’s crucial to have a centralized data repository or data warehouse that aggregates information from the WMS, enterprise resource planning (ERP), learning management system (LMS), order management system (OMS), and other sources. This allows for real-time data access and ensures consistency. Using data analytics platforms like Tableau, Power BI, or custom BI solutions will make it easier to provide a unified view of key performance indicators.

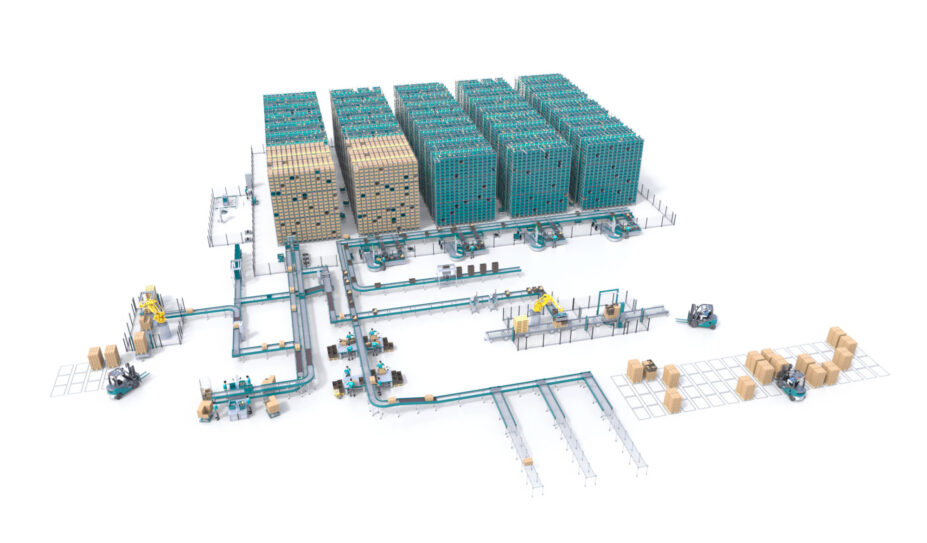

- Implement Advanced Warehouse Technologies: Automation is one of the most effective ways to reduce picking errors. By integrating advanced technologies such as Autonomous Mobile Robots (AMRs) and Automated Storage and Retrieval Systems (ASRS), warehouses can streamline operations and enhance accuracy. AMRs autonomously navigate the warehouse, picking and transporting items with precision, while ASRS automatically stores and retrieves items from designated locations, ensuring the correct product is picked each time.

How to Measure Order Picking Efficiency

Measuring the efficiency of your order-picking process is essential for identifying areas for improvement and ensuring that your strategies to reduce picking errors are effective. Key performance indicators (KPIs) for measuring picking efficiency include:

- Picking Accuracy Rate: The picking accuracy rate measures the percentage of orders picked without errors.

- Order Cycle Time: Order cycle time is the total time it takes to pick, pack, and ship an order. Reducing this time is crucial for improving efficiency and customer satisfaction.

- Units Picked per Hour: This KPI measures the number of units picked by workers or automated systems in an hour. It provides insight into the productivity of your picking process.

- Cost per Order: The cost per order metric considers all costs associated with picking, including labor, equipment, and errors. Reducing the cost per order while maintaining or improving accuracy is a key goal for efficient warehouse operations.

- Error Rate: The error rate measures the number of picking errors made over a certain period. Monitoring this rate can help identify trends or spikes in errors, prompting further investigation and corrective actions.

- Employee Turnover Rate: A high employee turnover rate can indicate issues with job satisfaction or training. Frequent turnover can lead to more picking errors, as new workers may be less familiar with the processes and systems.

The Exotec Skypod System: Error-Proof Picking

The Exotec Skypod system utilizes innovative goods-to-person robotics to provide error-proof picking. Robots transport goods between high-density storage racks and ergonomic picking stations. These stations feature easy-to-use screens that guide operators on what, where, and how many items to pick, with help from pick-to-light systems.

Take the Skypod system virtual tour to learn more about how Exotec can optimize your warehouse operations.

Featured In

Share

Insights

-

April 15, 2025Top Warehouse Trends for 2025: Future of Automation

-

April 9, 2025Material Handling: Basics, Benefits, & Automation

-

April 4, 2025Complete Guide to Pick-and-Place Automation

News

-

March 24, 2025Exotec Showcases Next-Gen Skypod System at ProMat 2025

-

March 17, 2025Exotec Announces Partnership with Oxford Industries to Implement Next Generation Skypod System in New Multi-Brand Distribution Center

-

February 27, 2025Colruyt‘s Collect&Go continues its automation journey with Exotec

Events

-

May 7, 2025Exodinner: Indianapolis, IN

-

May 22, 2025 | Cincinnati, OHExotour: Cincinnati, OH

-

May 28, 2025Exodinner: Vancouver, BC